At CVF we have over 50+ years of automation experience and a vast collection of products to perfectly suit your automation needs!

Feeder bowls

Vibratory Feeders

-

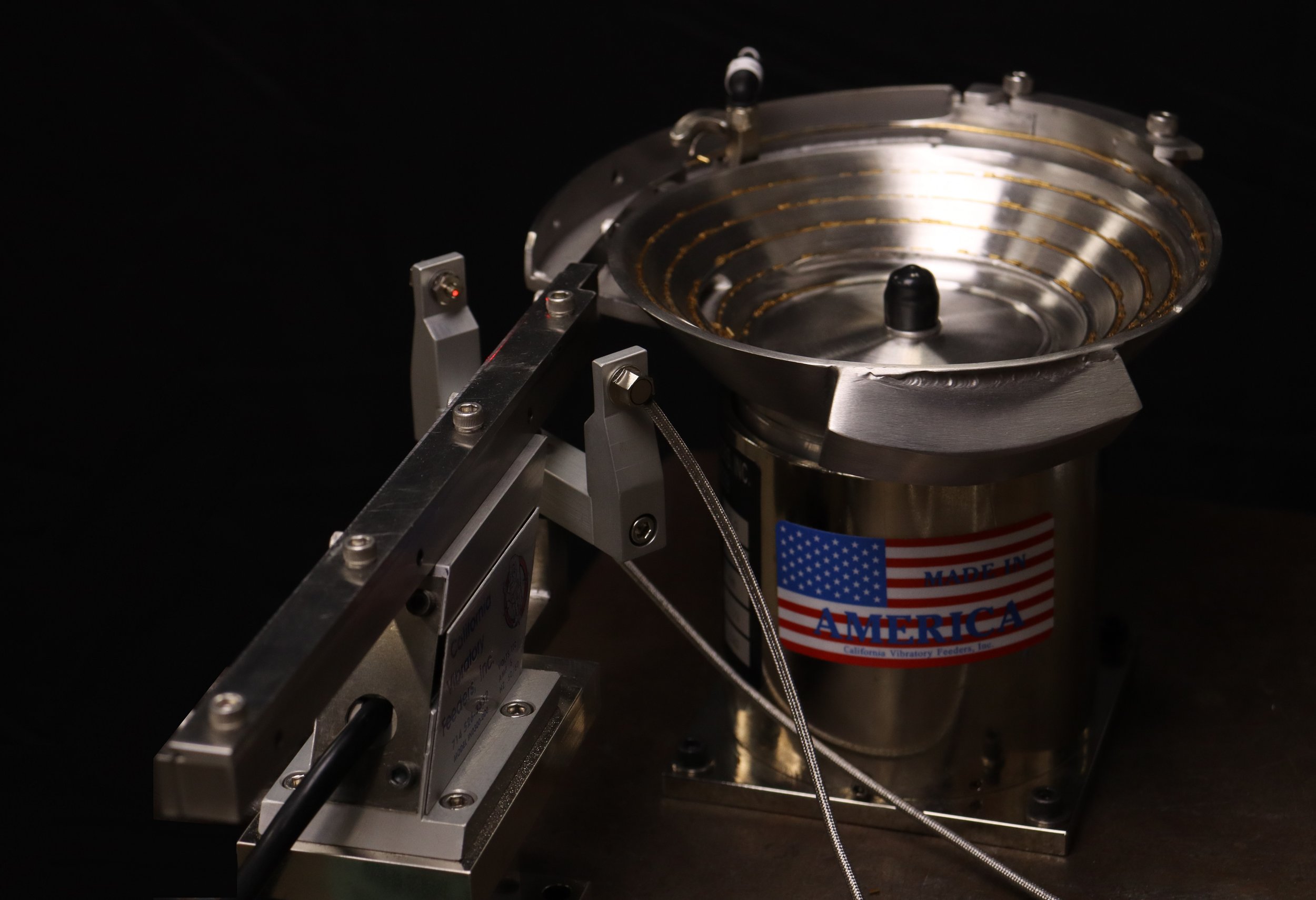

Vibratory feeder bowls offer a cost-effective and efficient solution for parts feeding needs. Operating through electromagnetic drive-induced vibration, they move parts along a spiral track, ensuring only correctly aligned parts pass through. Designed for small, lightweight, and challenging materials, these feeders deliver high-quality part delivery at elevated feed rates. These versatile machines provide the vital interfaces that reduce labor requirements and operator fatigue while helping to maintain high production levels.

-

CVF specializes in providing top-notch vibratory feeders tailored to meet your unique requirements. Our diverse range includes multi-lane vibratory feeders for high-speed applications, multi-bowl vibratory feeders for efficient processing, and various sizes ranging from 6” to 30”. With our expertise, CVF is dedicated to crafting and customizing vibratory feeder solutions to precisely match your specifications, ensuring optimal performance in your operations. These adaptable machines play a crucial role in minimizing labor demands and alleviating operator fatigue, all while contributing to the maintenance of elevated production levels.

Centrifugal Feeders

-

California Vibratory Feeders, Inc. offers Centrifugal Bowl Feeders as an alternative to vibratory feeders. These feeders excel in tasks similar to vibratory feeders but boast additional features, such as the ability to handle parts and operate at higher feed rates. Unlike their vibratory counterparts, centrifugal feeders utilize an angled, spinning disk to cast parts to the outer edge of the bowl, eliminating the need for vibration or tracks. This unique process makes them ideal for applications demanding gentle part handling as well as providing the vital interfaces that reduce labor requirements and operator fatigue while helping to maintain high production levels.

-

Opting for a multi-bowl system of Centrifugal Bowl Feeders provides a host of benefits over traditional vibratory feeders. The ability to handle parts and operate at higher feed rates remains a standout feature, providing versatility in handling diverse materials. With the elimination of vibration or tracks through the use of angled, spinning disks, our multi-bowl system ensures gentle part handling, making it an ideal solution for applications where precision and reliability are paramount. These adaptable machines play a crucial role in minimizing labor demands and alleviating operator fatigue, all while contributing to the preservation of elevated production levels.

Conical and cascades

-

These versatile machines play a pivotal role in reducing labor requirements and easing operator fatigue, all while contributing to the maintenance of high production levels. The small stature of our conical bowls work perfectly in helping to reduce recirculation of the product as it is introduced to special tooling. Our conical bowls work great for applications that include silicone or rubber stoppers.

-

The Cascade-style feeder bowl from California Vibratory Feeders offers a superior solution to address key challenges in parts handling. Specifically engineered to reduce recirculation of parts and minimize damage due to fall height, the design eliminates the need for a return pan. The open configuration ensures a seamless flow by preventing jamming between interior tracks, enhancing overall operational efficiency. Additionally, the cascade feeder's small sizes contribute to a reduced footprint, making it an ideal choice for space-conscious applications without compromising performance. Elevate your material handling processes with the precision and reliability of our Cascade-style feeder bowl.

Inline Feeders

-

Inlines (linear inline drive units) are automated equipment feeding devices which are designed to help store product. These units not only keep parts flowing but also allow for parts to be stored efficiently in the product queue, for future assembly, or select operations.

-

Gravity Tracks rely on gravity to move parts. These versatile options complement our vibratory and centrifugal bowl feeders, allowing us to cater to a diverse range of automation needs and preferences. These gravity tracks all ow for the storage of parts before their next step in the automation process with out the need for a drive unit.

-

CVF also provides airveyors (positive airveyor linear tracks) for customers who have distinct preferences. Airveyors utilize air instead of a mechanical drive to move parts between stages, offering a reliable solution for high feed rates.

-

Here at CVF we strive to supply the parts industry with only the best products available. Conveyors are designed for efficient parts movement from one processing or manufacturing step to another. provide the vital interfaces that reduce labor requirements and operator fatigue while helping to maintain high production levels. Variable speeds allow the user to use the CVF parts conveyor in a wide range of parts movement applications. These units can be supplied in any lengths required by the user.

Sound Enclosures and Tables

-

Industrial equipment must adhere to sound level considerations, ensuring a safe environment for all. Our sound enclosures are constructed with extruded aluminum and ¼” lexan sides, offering 360-degree visibility. The top and sides can be hinged for easy access. Our custom sound enclosures are designed to fit any CVF vibratory feeder bowl, with the standard size accommodating bowls ranging up to 30” in diameter.

-

The tables here at CVF are specifically designed to help support feeder bowls and other additional components. We offer several types of support tables to best fit your equipment needs. Our support tables are constructed of Blanchard ground steel and are mounted on a steel tubing frame that includes leveling pads. Mobile table options are available upon request. This allows for each system to be used in as many different areas of your building as possible.

Prefeeders and hoppers

-

Here at CVF we manufacture and supply vibratory storage hoppers that hold a bulk amount of parts to reduce operator interaction with the feeder. We offer a wide variety of vibratory storage hoppers with many sizes to choose from.

Vibratory storage hoppers are a big benefit to feeder bowls with high feed rates. Since these feeder bowls need to be consistently filled, vibratory storage hoppers are used to automatically refill the feeder bowl once the fill level falls below a certain level.

-

Elevating prefeeders play a very important role in the parts business. Elevating prefeeders are used to supply parts at heights above operators physical range. The cost saving benefits of using elevating prefeeders is invaluable. Not only will the use of elevating prefeeders save on operating labor cost, but elevating prefeeders provide the functionality of floor loading along with the capability of performing at various heights that are needed to satisfy certain requirements. The belt elevator is available in standard heights 6 inch-wide to 12 inch-wide cleated belt. The bulk storage hopper is offered in various sizes. The belt elevator unit includes motor and controller. Operation of the system may be automatically controlled with a bowl level switch located over the bowl to control the on off cycle of the elevating prefeeder preventing over feeding.

-

Our CVF tray style vibratory bulk storage hoppers offer a lower loading height that is operator-friendly and allows feeding into the bowl through the return pan wall instead of over the top of the bowl. The open design ensures uniform parts flow, eliminating jams, nesting, or bridging in the hopper bin. Additionally, it facilitates easy cleanout for smooth changeover between different part sizes or styles.

Don’t see what you’re looking for here?

Contact us about custom projects!

sales@calvibes.com

800.354.0972

1725 N. Orangethorpe Park

Anaheim CA 92801

Hours

Monday–Friday

7am–3:30pm